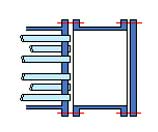

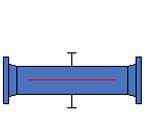

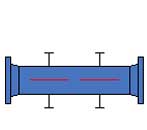

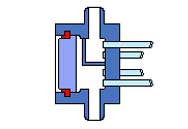

Fixed Tubesheet Heat Exchanger

Fixed tubesheet heat exchanger design

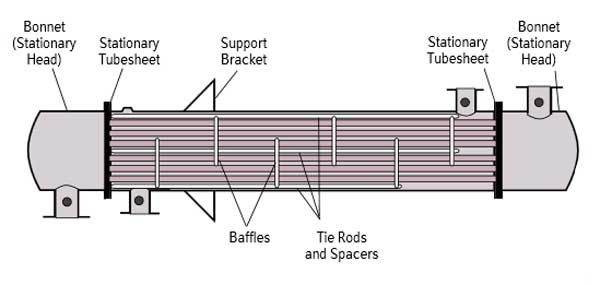

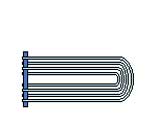

- At both ends of the tube sheets of fixed tubesheet heat exchanger are connected and fixed with the shell by welding, the construction of this kind of heat exchanger is simple.

- Fixed tubesheet heat exchanger features compact, it have the most calandrias in the same shell diameter.

- In the shell side flow with a baffle plate, the bypass is minimal, and the tube side can be divided into any number of passes.

- When the expansion difference is larger, an expansion joint should be equipped to reduce the thermal stress, caused by the temperature difference between tube side and shell side.

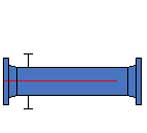

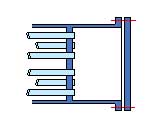

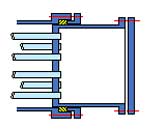

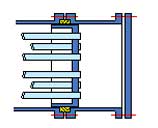

Fixed Tubesheet Heat Exchanger Structure

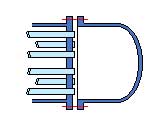

Fixed tubesheet heat exchanger cleaning

Fixed tubesheet heat exchanger cleaning is one of the most important part during the process of heat exchanger. The two tube sheets are supported by the heat exchanger tube, the tube sheet is thin, and the cost is low, also the inside of each tube can be cleaned. But it is difficult to clean the shell by the mechanical method, so this kind of heat exchanger can be applied to the not easy scaling and clean fluid.Fixed tubesheet heat exchanger TEMA

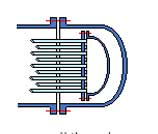

The following table illustrates the TEMA type fixed tubesheet heat exchanger for various constructions, including stationary head types, shell types, and rear head types. For example, an AEL fixed tubesheet heat exchanger may have a removable channel cover, one-pass shell, fixed tube sheet.| Stationary Head Types | Shell Types | Rear Head Types | |||

| A |

channel and removable cover |

E |

one pass shell |

L |

fixed tubesheet like 'A' stationary head |

| B |

.jpg) bonnet (integral cover) |

F |

two pass shell with longitudinal baffle |

M |

fixed tubesheet like 'B' stationary head |

| C |

channel integral with tubesheet and removable cover |

G |

split flow |

N |

fixed tubesheet like 'C' stationary head |

| N |

.jpg) channel integral with tubesheet and removable cover |

H |

double split flow |

P |

outside packed floating head |

| D |

special high pressure closure |

J |

divided flow |

S |

.jpg) floating head with backing device (split_ring) |

| K |

kettle type reboiler |

T |

pull through floating head |

||

| X |

cross flow |

U |

u tube bundle |

||

| W |

packed floating tube sheet with lantern ring |

||||

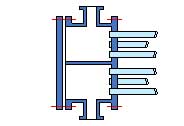

Fixed tubesheet heat exchanger application

- Fixed tubesheet heat exchanger is more suitable for the media temperature difference is not large, or the temperature is high but pressure of the shell side is low, also available for the not easy to scale condition with clean media or the condition that can be cleaned chemically in the shell side.

- The fixed tubesheet heat exchanger construction is simple and low manufacturing cost, with easy tube pass cleaning process and wide range of specifications, fixed tube sheet heat exchanger is widely used in engineering

- The shell side cleaning is difficult, for the more dirty or corrosive media, fixed tubesheet heat exchanger should not be used.

Ordering Information:

- Please specify the type or standard you need, ASME standard or TEMA type. If you want a TEMA type heat exchanger please specify the type according to the above TEMA designation table, like TEMA Type BEM.

- Please specify the material you need, we provide material from Steel, Stainless Steel to Copper Alloys. Other material options are also available.

- Please specify the size you need. Like 1, 2, 4 or 6 pass and shell diameter, or other important dimensions you think.