Design of Vertical Storage Tank

Carried Standard

National standard: GB 50128-2005 Construction and acceptance standard for vertical cylindrical steel welding oil tankInternational standard: API-650-2007 Standard of steel weld oil storage tank

Construction Specification

Construction method: chain flip-chip method is usually used for common vertical oil storage tank:

construction preparation→material inspection→cutting→machining→inspection→welding of the center plate at the bottom of tank→welding of the arch edge plate at the bottom of tank→setting up the center post and umbrella stand→installation and welding of top ring→installation and welding of edge and steel angle→assembling of temporary arch bracket→installation of leading chain lifting device→installation and welding of arch roof→installation and welding of the lower circle→Jack-up the top circle shell plate→welding of circular seam→installation and welding of every circular seam→installation and welding of bottom circle, bottom plate and angle seam→installation and welding of edge plate of bottom plate→inspection→installation of accessories→vacuum test→test→settlement observation→hand over

Prefabricating of tank: three arc sample plates: one is for checking curvature of arch roof, chord length of which is no less than 2m; one is for checking the deformation of the edge of vertical weld seam, chord length of which is no less than 1m; one is for checking the deformation of vertical weld seam, chord length of which is no less than 1m.

Assembling of tank: According to the sequence for installing oil tank, the lower surface of bottom plate should be done the anticorrosion work before installation of bottom plate. A cross center line should be drew up on the surface before layout of bottom plate. The deviation with the center line remarked by civil construction should be within the scope of permit.

Inspection of welding and weld seam: To evaluate the welding process of butt joint, T fillet weld and tube plate according to JB4708-92 The evaluation of welding process of steel pressure vessel. To make the guide book of welding process in the site, the person who do the NDT for weld seam of oil tank. RT will be done according to the specification of GB3323-87 Radiogram and quality of butt joint welded by steel melt weld.

Inspection Methods

Tank test: Vacuum test will be adopted for all bottom plates and the vacuum degree should not be less than 53Kpa. The penetrate test will be used to reinspect.

To do tank water filling test, up and down test of floating disc and observation of foundation settlement. Then to close the holes of upper part temporarily and to open light holes on the roof and then to fill water into tank. The water should be fresh water and the temperature should be lower than 5℃. The pressure should be kept for hours.

The water filling test, strength test and stability test for shell plate and roof plate: To close the light holes, foam holes and vent holes on the roof when the water level reaches to 1m and then to fill the water continuously. To observe the pressure through the pressure gauge on the roof. The stability test will be done after water filling test. When the water level reaches the maximum operation liquid level, to close the opening and drain the water slowly. When the negative pressure generated in the tank, to monitor the negative pressure number strictness. When the negative pressure number reaches 200mm, to stop draining water immediately and to fill water, making the pressure in the tank be normal.

Crack detection: To do penetration test and MT for the fillet weld seam of joint angle and stiffening plate on the tank.

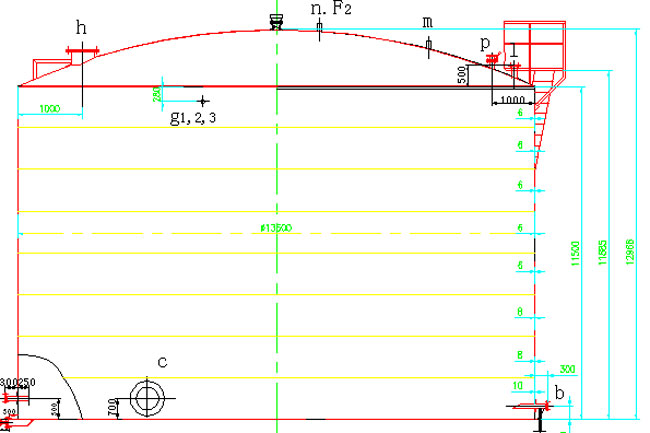

Vertical Storage Tank Design Drawing