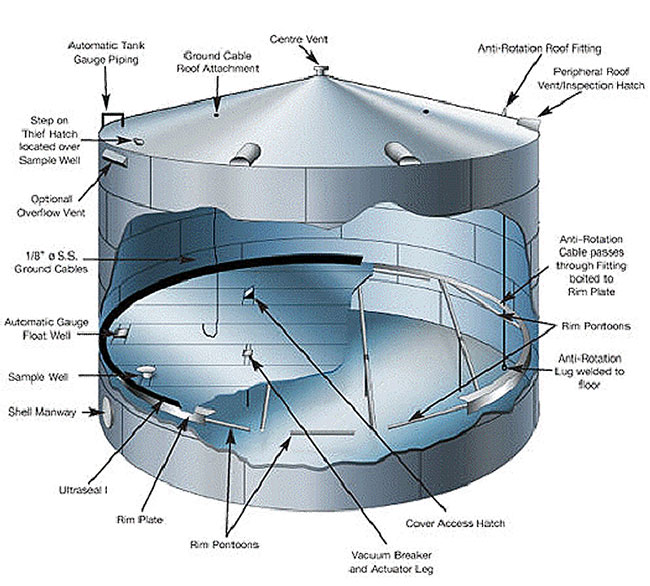

Internal Floating Roof Tank

Standard for the implementation of internal floating roof tanks

- Domestic design standards: GB50341-2003 "vertical cylindrical steel welded oil tank design specification"

- Domestic construction standards: GB50128-2005 "vertical cylindrical steel welded oil tank construction and acceptance specification"

- Foreign design standards: API650-2007 "steel welding oil tank standard"

Internal floating roof tank

Internal floating roof tank is known as the internal floating roof tank, floating roof tank, storage tank of the floating plate, internal floating disc, tanks and other, specifically refers to the tanks and tank installation of aluminum, stainless steel material of the inner floating roof to prevent tank of liquid volatilization of a kind of environmental protection and economic, belongs to the dome tank fitting floating roof, dome roof tank and internal floating roof structure is combined with the volatile liquid tank, combining with the tank outside the vault and the inside of the tank floating roof, at present in gasoline, aviation kerosene and volatile stronger chemical liquid has been widely used.Internall floating roof structure

Internal floating roof or internal floating disc is that floats on the oil tank liquid level with the oil and liquid lifting floating roof, covering the surface of the liquid is currently recognized as the most ideal reduce oil evaporation loss in the most economical, the most practical method using the inner floating roof.

Internal floating roof oil tank features:

- Has obvious environmental and economic benefits: the specific climatic conditions, according to the history it is said that data show that using internal floating roof 3-6 months of internal reduction of volatile oil and gas equivalent economic value to the inner floating roof installation cost of procurement, namely within six months can recover inner floating roof cost. Suitable for a variety of docking tank and lap tank, it itself does not pollute the oil or chemicals, reduce liquid volatilization loss, prevent air pollution, is an ideal inner floating roof floating plate and has the advantages of low cost, short construction period resistance corrosion, does not occupy a volume, long service life and other characteristics.

- With the characteristics of high safety: inner floating disc floating on the surface, resulting in liquid phase without evaporation space, can reduce the evaporation loss of 85% - 90%; at the same time, through the floating plate blocking of the air and the liquid storage, to reduce air pollution, reduce the fire hazard degree.

- With the advantages of long: inner floating roof tank inside because there is no gas space on the surface, reducing the in the liquid in tank and conveying oscillations generated in the process to prevent liquid storage on the inner wall of the tank to produce impact or pressure becomes larger, reduce the top of the tank and the tank wall corrosion, prolong the service life of the tank.

Internal floating roof oil tank applicable scope:

- working pressure: atmospheric storage tank;

- working temperature: -30 150;

- liquid medium: oil, including such as naphtha, gasoline, diesel, kerosene and crude oil, fuel oil, heavy oil, benzene, xylene, ethanol, methanol;

- storage tank capacity: the current design considerations generally not more than 10000 cubic meters.