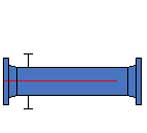

floating head heat exchanger

Best Floating Head Heat Exchanger for Sale

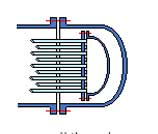

Floating head heat exchanger is one of the most used heat exchanger. As shown in the name of it, in this design, one end of the tubesheet is fixed to the shell, while the other one can “float” freely inside the shell. Generally, both the shell and tube bundle are free of expansion, this permits no thermal stress is produced between shell and tube bundle, when the temperature difference of two medium is large. In addition, it is easy to inspect and clean mechanically the heat exchanger as the tube bundle can be removed absolutely. Floating head heat exchanger is widely used for the service where the temperature is high between the shell and tube bundle, or the dirty service, like the petroleum refinery.With high reliability and wide adaptability, floating head heat exchanger has accumulated a wealth of experience during the long – term using process, and promoted its development constantly. So far, among all kinds of heat exchangers, floating head heat exchanger is still in a leading position.

Floating Head Heat Exchanger Design

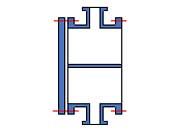

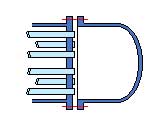

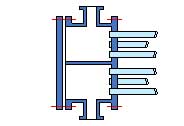

According to different requirements, the floating head on a floating head heat exchanger can be designed into various types, in addition to consider that the tube bundle can move freely within the device, we must also take into the convenience of maintenance, installation, and cleaning for the heat exchanger.Generally, there are four basic types of floating head heat exchanger – outside packed stuffing box (TEMA P), outside packed lantern ring (TEMA W), the floating head with backing device (TEMA S), and pull through (TEMA T) designs.

ANSON can manufacturer various kinds of floating head heat exchangers accordance with the TEMA, API660, and JISB8249. Other special requirements are also available.

.jpg)

Pull Through Floating Head Heat Exchanger (TEMA T)

.jpg)

Pull Through Floating Head Heat Exchanger (TEMA S)

| Stationary Head Types | Shell Types | Rear Head Types | |||

| A |

channel and removable cover |

E |

one pass shell |

L |

fixed tubesheet like 'A' stationary head |

| B |

.jpg) bonnet (integral cover) |

F |

two pass shell with longitudinal baffle |

M |

fixed tubesheet like 'B' stationary head |

| C |

channel integral with tubesheet and removable cover |

G |

split flow |

N |

fixed tubesheet like 'C' stationary head |

| N |

.jpg) channel integral with tubesheet and removable cover |

H |

double split flow |

P |

outside packed floating head |

| D |

special high pressure closure |

J |

divided flow |

S |

.jpg) floating head with backing device (split_ring) |

| K |

kettle type reboiler |

T |

pull through floating head |

||

| X |

cross flow |

U |

u tube bundle |

||

| W |

packed floating tube sheet with lantern ring |

||||

Floating Head Heat Exchanger Advantages

- Tube bundle can be pulled out to facility cleaning the tubeside and shellside.

- Temperature difference between two medium is not limited.

- The heat exchanger can be operated under high temperature and high pressure, the average temperature is less than or equal to 450℃,and pressure is less than or equal to 6.4MPa.

- This kind of heat exchanger is suitable for the serious scaling occasion.

- This kind of heat exchanger is suitable for the easy corrosion occasion.